Table of Contents

Introduction: The Soul in Every Stitch

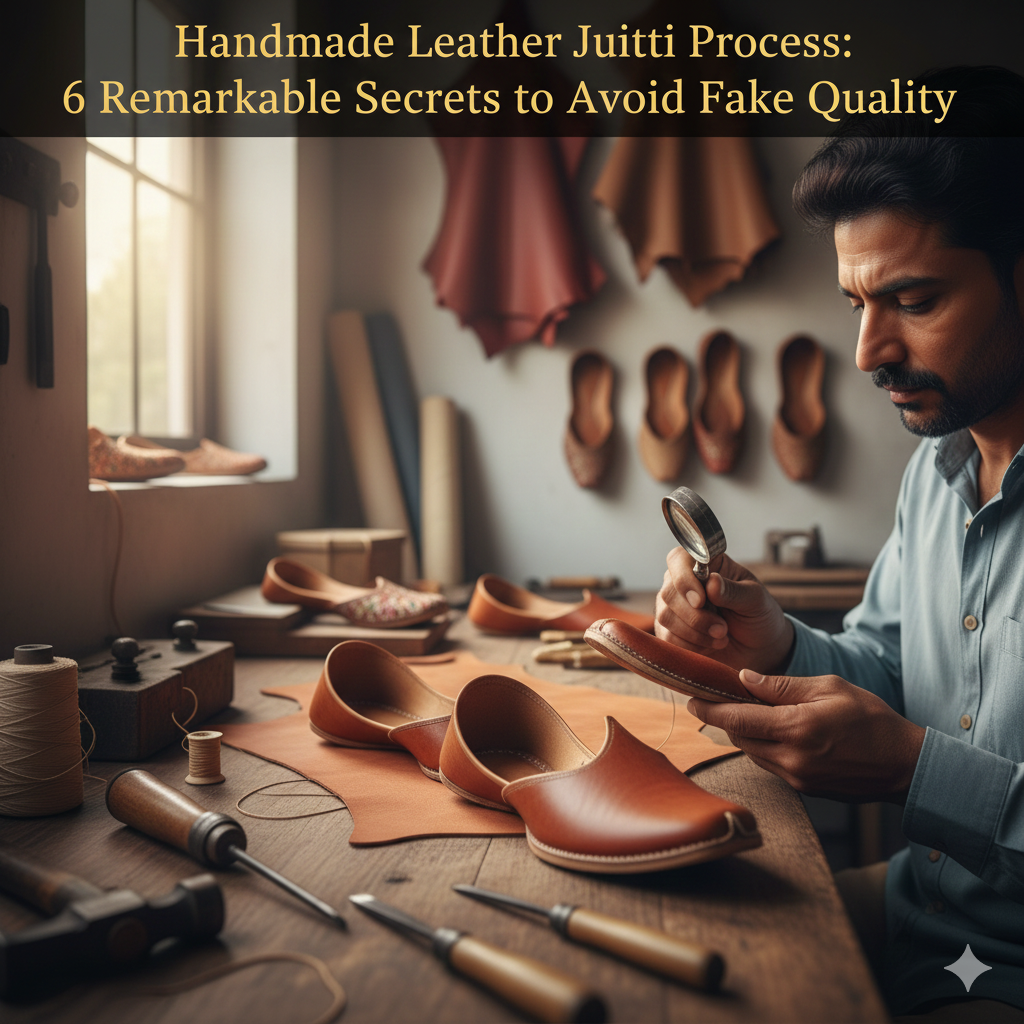

The handmade leather jutti process is a centuries-old tradition that creates wearable art through cultural preservation and human patience. Unlike mass-produced imitations, authentic juttis sustain artisan families and improve with age. Understanding these six remarkable secrets helps you identify true craftsmanship, avoid convincing fakes, and support a heritage that tells a story for generations.

Secret #1: The Sacred Selection – Where Every Hide Tells a Story

The journey of authentic ethnic footwear begins with a profound relationship between artisan and material. The handmade leather jutti process starts with leather selection that approaches reverence. Master artisans don’t merely purchase materials—they curate them with an eye developed through generations. Full-grain leather, taken from the strongest part of the hide, represents the gold standard. This material retains the skin’s natural grain, complete with its unique markings and characteristics. Unlike corrected leather (sanded and refinished) or bonded leather (shredded and reconstituted), full-grain develops a beautiful patina over years of wear, becoming more distinctive with age.

Vegetable tanning represents another hallmark of quality in the handmade leather jutti process. This ancient method uses natural tannins from bark, leaves, and fruits—often acacia, babul, or myrobalan in traditional Indian practice. The process takes 30 to 60 days, compared to chemical tanning’s few hours. Vegetable-tanned leather breathes naturally, molds to the foot’s contours, and ages gracefully. It also possesses a distinctive, pleasant earthy scent completely absent from chemical-treated alternatives. Artisans examine each hide against the light, checking for consistent thickness, natural markings, and structural integrity. They reject pieces with scars, tick marks, or inconsistent texture—imperfections that might cause weakness in the finished traditional shoes.

The regional variations in leather selection reveal fascinating aspects of the handmade leather jutti process. In Punjab, water buffalo leather provides exceptional durability for agricultural communities. Rajasthan’s desert artisans often prefer goat leather for its fine grain and flexibility. Camel leather, though less common, offers unique texture and insulation properties prized in colder regions. Each choice reflects generations of problem-solving—specific responses to climate, occupation, and cultural preferences. When examining potential purchases, perform the “pinch test”: gently pinch the leather. Quality material should show some give and return smoothly to shape. Synthetic alternatives or poor-quality leather will either resist bending or show permanent creasing.

Secret #2: The Living Blueprint – Pattern Mastery as Cultural Memory

Before scissors touch leather, the handmade leather jutti process enters its most intellectual phase: pattern creation. The khaka (pattern) represents far more than a template—it’s a living archive of cultural knowledge, anatomical understanding, and aesthetic tradition passed through generations. Each family of artisans guards their pattern books like heirlooms, with some designs dating back centuries. These patterns encode regional identities: Jaipur’s elegant curves differ distinctly from Jodhpur’s bold geometrics or Punjab’s vibrant phulkari-inspired layouts.

The creation of these patterns demonstrates the sophistication embedded in the handmade leather jutti process. Master artisans don’t simply trace outlines—they engineer three-dimensional forms on two-dimensional paper. They account for leather stretch, foot biomechanics, and decorative requirements simultaneously. The pattern includes “ease”—intentional extra space that allows for foot movement and leather behavior. Traditional patterns feature curved seams rather than straight lines, following the foot’s natural contours for superior comfort. This anatomical intelligence, accumulated over centuries, creates traditional shoes that feel different from their first wearing—they embrace rather than constrain.

Transferring patterns reveals another layer of the handmade leather jutti process. Artisans use specialized chalk that marks without damaging the leather’s surface. They position patterns according to the hide’s grain direction—aligning stress points with the leather’s strongest orientation. This mindful placement minimizes waste while maximizing structural integrity. Machine production, in contrast, uses digital patterns placed for maximum material efficiency with little regard for natural variations. The human touch in authentic ethnic footwear makes constant micro-adjustments based on what each unique piece of leather reveals.

Regional pattern variations tell cultural stories within the handmade leather jutti process. The curled mohri (toe) of Jodhpur juttis originated from practical needs—preventing the foot from slipping through horse stirrups. Jaipur’s more refined toe shape reflects courtly elegance and indoor use. Punjabi juttis often feature slightly raised heels, historically practical for avoiding mud in agricultural fields. These aren’t arbitrary design choices but evolved solutions to specific environmental and social conditions. When examining juttis, look beyond decoration to underlying form—the pattern’s intelligence reveals itself in how the footwear fits, moves, and feels during wear.

Secret #3: The Dance of Blade and Hand – Cutting as Meditation

The moment blade meets leather represents a point of no return in the handmade leather jutti process. Here, precision becomes poetry, and the artisan’s hand executes decisions made long before. Traditional cutting tools—curved knives called chamkis or kharaus—extend the artisan’s intention with minimal interference. Unlike industrial clicker presses that stamp dozens of layers simultaneously, hand cutting engages with each piece of leather individually. The artisan feels resistance variations, adjusts pressure accordingly, and honors the material’s unique character.

The cutting phase of the handmade leather jutti process demands complete presence. Breathing synchronizes with movement. Eyes follow chalk lines while hands maintain consistent angles. The leather rests on a smooth wooden board, often worn concave from generations of use. Left-handed artisans develop slightly different techniques than right-handed counterparts, creating subtle variations that become their signatures. This human element disappears in machine production, where every piece emerges identical—technically perfect but spiritually empty. The slight irregularities of hand-cut leather pieces aren’t flaws but evidence of thoughtful engagement.

Waste management reveals the ecological intelligence embedded in the handmade leather jutti process. Smaller pieces become decorative elements, straps, or reinforcement patches. Scraps too small for juttis might become children’s footwear, keychains, or decorative elements. Nothing returns to the earth without offering maximum utility first. This contrasts sharply with industrial production where efficiency often creates substantial waste. The artisan’s economy extends beyond financial considerations to material reverence—a relationship with resources increasingly rare in modern manufacturing.

Tool maintenance forms a ritualistic aspect of the handmade leather jutti process. Blades receive regular honing on natural stones. Handles worn smooth from decades of use fit perfectly in practiced palms. These tools often pass through generations, accumulating stories with each repair and modification. An artisan might use their grandfather’s knife for certain cuts and their own for others—each blade possessing different character from years of specific use. This intimate tool relationship creates results no machine can replicate. When examining ethnic footwear, look closely at cut edges: hand-cut edges show slight beveling and gentle irregularities; machine-cut edges appear perfectly uniform and often slightly melted from friction heat.

https://images.unsplash.com/photo-1562157873-818bc0726f68

Secret #4: The Embroidery Universe – Where Thread Becomes Language

Embroidery represents the most visible artistry in the handmade leather jutti process, transforming functional footwear into narrative objects. This stage requires not just technical skill but artistic vision, patience measured in days rather than hours, and knowledge of symbolic languages. Traditional techniques vary dramatically by region: Aari work uses a hooked needle for chain stitching, Mochi Bharat creates reversible patterns, Gota Patti applies metallic ribbon, Phulkari covers surfaces with floral motifs, and Shisha incorporates tiny mirrors for light and protection.

The embroidery framework, or adda, serves as the artist’s easel in the handmade leather jutti process. This wooden stretcher holds leather at perfect tension—too loose creates puckering, too tight risks tearing. Natural light remains essential; artificial lighting distorts color perception and strains eyes during hours of meticulous work. Thread selection follows traditional wisdom: silk for sheen and strength, cotton for matte durability, metallic wires for ceremonial pieces. Each material behaves differently, requiring adjusted techniques and tensions learned through years of practice.

Symbolic language encodes cultural values within the handmade leather jutti process. Peacocks represent beauty and royalty, parrots symbolize love and communication, mango motifs (keri) denote fertility and prosperity, geometric patterns reflect cosmic order, and floral designs celebrate nature’s abundance. These aren’t arbitrary decorations but visual stories connecting wearers to cultural narratives. Color choices follow similar symbolic systems: red for weddings and celebrations, yellow for spring festivals, green for new beginnings, white for mourning. This symbolic intentionality contrasts with machine embroidery that replicates patterns without understanding their meanings.

The time commitment in this phase of the handmade leather jutti process astonishes modern sensibilities. Simple designs require 15-20 hours per pair. Elaborate wedding juttis might demand 80-100 hours spread over weeks. During this time, the artisan enters a meditative state—hands moving almost autonomously while mind focuses on pattern integrity and tension consistency. This profound engagement creates results that machines cannot approach: stitches with slight organic variations, threads that follow natural contours, and patterns that breathe with the leather. Machine embroidery appears flat, uniform, and mechanically perfect but lacks the vitality of handwork.

Examining embroidery reveals authenticity in ethnic footwear. Turn juttis inside out: hand-embroidered pieces show neat knots and consistent tension on the reverse side; machine embroidery reveals glue residues, loose threads, or backing materials. Observe stitch density: handwork allows for varied spacing according to design needs; machine work maintains rigid uniformity. Feel the surface: hand embroidery has dimensional quality with slight variations in height; machine work feels flat and uniform. These subtle distinctions separate traditional shoes of heritage from factory-produced simulations.

Secret #5: The Structural Alchemy – Assembly as Engineering

Assembly represents the architectural phase of the handmade leather jutti process, where disparate elements unite into functional harmony. This stage demonstrates why authentic juttis last decades while fakes disintegrate within seasons. Traditional assembly uses waxed linen thread—a material that actually strengthens with initial wear as fibers compact. The threading technique involves two needles working simultaneously from opposite sides, creating locked stitches that won’t unravel if cut. This method, ancient and brilliant, creates seams stronger than the surrounding material.

The patti (border) attachment exemplifies precision in the handmade leather jutti process. This narrow leather strip finishes edges while providing structural reinforcement. Artisans use specialized curved needles that navigate tight spaces without tearing materials. Stitch density increases around stress points—toe areas, joint bends, and strap attachments receive extra attention. This thoughtful reinforcement anticipates wear patterns learned through generations of observation. Machine assembly cannot make these micro-adjustments, resulting in consistent but inadequately reinforced stitching throughout.

Sole attachment represents a philosophical divide in the handmade leather jutti process. Traditional methods use layered leather soles stitched directly to uppers—a technique requiring immense skill but creating unparalleled flexibility and durability. The artisan uses an awl to pierce holes before threading, preventing thread damage from friction. Some regions incorporate recycled tire soles (kharra) for added durability, attached with both stitching and minimal natural adhesive. Modern fakes rely heavily on synthetic glues that dry out, crack, and fail completely. The test is simple: bend the jutti. Traditional construction allows smooth flexion along natural foot lines; glued construction resists bending or creases unnaturally.

Lasting—shaping the assembled jutti—completes the structural phase of the handmade leather jutti process. Wooden lasts, often custom-carved for specific foot types, receive the softened leather assembly. Artisans gently persuade materials into perfect form, sometimes using specialized tools to smooth creases without damaging surfaces. This process sets the jutti’s final shape, ensuring left and right pairs mirror perfectly. Quality lasts become family treasures, worn smooth from decades of use and carrying the memory of thousands of feet they’ve helped shape.

https://images.unsplash.com/photo-1567401893416-8f3b46c27d16

Secret #6: The Finishing Perfection – Details That Speak Volumes

Finishing transforms assembled pieces into finished traditional shoes in the handmade leather jutti process. This phase separates adequate craftsmanship from exceptional artistry. Edge finishing begins the process—raw edges receive careful treatment with gum tragacanth or natural waxes that seal and smooth. Artisans then polish leather with proprietary oil blends, often family secrets combining neem oil for protection, mustard oil for flexibility, and natural pigments for color enhancement. Each application follows by hand rubbing that generates gentle heat, helping oils penetrate deeply.

Interior attention distinguishes authentic ethnic footwear in the handmade leather jutti process. Linings receive meticulous attachment—smooth seams, trimmed threads, and sometimes additional padding at pressure points. The insole might feature subtle arch support shaped through generations of anatomical observation. All interior surfaces undergo inspection for roughness or imperfections that might discomfort the wearer. This behind-the-scenes excellence defines luxury in traditional shoes—beauty that extends to unseen places.

Decoration finalization completes the visual narrative in the handmade leather jutti process. Tassels hand-tied with specific knots, bells chosen for particular tones, pom-poms made from leftover embroidery threads—these elements receive equal artistic attention. Placement follows traditional guidelines: bells at toes for musical movement, tassels at heels for elegant sway, mirrors positioned to catch light at specific angles. Each decorative choice serves aesthetic and sometimes symbolic purposes lost in mass production.

Quality control represents the final gatekeeper in the handmade leather jutti process. Master artisans examine each pair under natural light, checking for symmetry, consistency, and perfection. They wear-test samples, walking to ensure comfort and flexibility. They verify that decorative patterns align properly when feet stand naturally. This personal accountability—the artisan’s name literally attached to their work—creates quality assurance no factory inspection can match. Rejected pieces don’t reach customers but become learning tools for apprentices.

The aging consideration represents perhaps the most profound aspect of the handmade leather jutti process. Master artisans create with future patina in mind—selecting leathers that will develop character, using stitches that will settle into comfort, applying finishes that will mature beautifully. This forward-thinking creation contrasts with fast fashion’s planned obsolescence. Authentic juttis should improve with wear, molding to feet, softening at stress points, and developing unique coloration from sunlight and use. This anticipated evolution represents the ultimate luxury in traditional shoes.

The Temporal Reality: Why Time Equals Quality

Understanding time investment explains price differentials in authentic ethnic footwear. The complete handmade leather jutti process requires minimum 40-60 human hours for simple designs. Elaborate pieces demand 100-150 hours spread across multiple specialists. This timeline includes essential resting periods—leather must acclimatize between stages, embroidery needs tension adjustment, adhesives require proper curing. Rushing any phase compromises results, something traditional artisans refuse to do.

The collaborative nature of quality traditional shoes further explains value. Rarely does one artisan complete the entire handmade leather jutti process. More commonly, specialists excel in specific stages: a master cutter with decades of experience, an embroiderer renowned for particular motifs, an assembler with magical hands for seamless joins. This collaborative model represents centuries of refined specialization—the collective intelligence of generations focused on perfecting specific aspects of creation.

Seasonal considerations affect the handmade leather jutti process in ways factories ignore. Humidity impacts leather behavior and thread tension. Temperature affects adhesive curing and material flexibility. Traditional artisans adjust techniques according to weather patterns—working earlier in dry seasons, using different thread treatments during monsoons, allowing extended drying times in winter. This environmental responsiveness creates better results but limits production speed. The artificial consistency of climate-controlled factories cannot replicate this nuanced adaptation.

The learning timeline reveals why authentic craftsmanship cannot be rushed. Apprentices spend years mastering single aspects before attempting complete pieces in the handmade leather jutti process. A decade might pass before an artisan earns “master” designation. This extensive training ensures techniques survive with full integrity. Compare this to factory workers trained in weeks to operate specific machines without understanding the holistic process. The knowledge depth difference manifests in every detail of finished traditional shoes.

The Deception Detection: Your Comprehensive Authentication Guide

Armed with process knowledge, spotting fakes becomes straightforward. Begin with the holistic assessment: authentic ethnic footwear feels “alive” while fakes feel inert. Move to specific examinations:

Material Verification: Perform the water test—a drop on genuine leather absorbs slowly and darkens the area; on synthetics it beads or absorbs instantly with discoloration. Check the reverse side: real leather shows fibrous backing; bonded leather reveals mesh or fabric backing.

Structural Analysis: Bend the jutti sharply. Quality construction allows smooth flexion without creasing; glued constructions resist or crack. Examine stress points: authentic pieces show reinforcement stitching; fakes often have decorative stitching that doesn’t actually strengthen.

Stitch Scrutiny: Use magnification if possible. Hand stitches show slight spiral twisting in thread and minor spacing variations; machine stitches appear perfectly uniform with straight thread. Check stitch consistency on curved areas: handwork maintains tension through curves; machine work often shows puckering.

Edge Examination: Authentic edges in the handmade leather jutti process show careful finishing—smooth, slightly rounded, consistent. Machine-finished edges often appear sharp, slightly melted from friction heat, or uneven where different materials meet.

Interior Inspection: Turn juttis inside out. Authentic pieces have neatly finished interiors with consistent seams; fakes reveal glue spills, rough edges, and unfinished areas. Check for lining quality: natural fabrics indicate care; synthetic non-breathable materials suggest corner-cutting.

Weight and Balance: Genuine leather has substantial but not heavy feel. Synthetic alternatives often feel surprisingly light or unnaturally heavy. Balance the jutti on your finger—well-made traditional shoes balance at the arch; poorly made ones tilt toward toe or heel.

Documentation and Provenance: Authentic artisans and ethical brands provide information about origins, materials, and makers. Vague descriptions like “handcrafted style” or “ethnic design” often disguise machine production. True craftspeople proudly share their process and heritage.

Price Reality Check: Calculate approximate labor hours versus asking price. The handmade leather jutti process cannot produce quality at fast-fashion prices. If the math doesn’t work—artisans earning fair wages for dozens of hours—you’re likely examining clever imitation.

The Care Continuum: Honoring Craft Through Maintenance

Proper maintenance extends the life of authentic ethnic footwear while honoring the artisan’s effort. Begin with protective measures: apply natural waterproofing before first wear, using beeswax-based products rather than silicon sprays that can damage leather. Store in breathable cotton bags away from direct sunlight, with acid-free tissue paper maintaining shape.

Cleaning requires gentle approaches in the handmade leather jutti process tradition. Use soft brushes for dust, damp cloths for stains, and never submerge in water. For serious soiling, professional cleaning by specialists familiar with traditional materials preserves integrity. Avoid commercial leather products containing solvents that can strip natural oils and damage embroidery threads.

Conditioning follows seasonal rhythms in traditional care. Pre-monsoon conditioning prepares leather for humidity; post-monsoon treatments address moisture effects; winter conditioning prevents drying from indoor heating. Use natural conditioners—lanolin-based creams or traditional oil blends—applied sparingly and buffed thoroughly. Over-conditioning can soften leather excessively and stain embroidery.

Repair philosophy for traditional shoes differs from disposable fashion. Small issues addressed immediately prevent major damage. Find cobblers experienced with handmade construction—they’ll understand reinforcing weak stitches, reattaching soles properly, and color-matching repairs. For embroidery damage, some artisans offer repair services, though complex work may require returning to original makers.

Rotation represents simple but effective preservation. Like all leather goods, traditional shoes benefit from rest periods between wears. This allows moisture evaporation and fiber recovery. Maintaining multiple pairs for different occasions distributes wear and extends all their lifespans. This practice honors the resources and labor invested in each pair’s creation.

Storage intelligence protects your investment. Avoid plastic containers that trap moisture. Use shoe trees specifically shaped for juttis’ unique form. Keep away from heat sources and maintain moderate humidity. For long-term storage, thorough cleaning and conditioning precede wrapping in acid-free paper before boxing in breathable containers.

The Ethical Imperative: Your Purchase as Cultural Stewardship

Choosing authentic traditional shoes represents conscious cultural stewardship. The handmade leather jutti process sustains more than individual artisans—it supports entire ecosystems of tanners, thread-makers, tool-smiths, dyers, and their families. Each purchase votes for preservation of intangible cultural heritage increasingly threatened by globalization and automation.

Fair compensation forms the ethical foundation. Authentic artisans deserve living wages for their skilled labor. When you bypass intermediaries to purchase directly or through ethical marketplaces, more money reaches makers. This economic justice enables master artisans to train apprentices, ensuring techniques survive another generation. The alternative—driving prices down through mass production—erodes quality and ultimately destroys the craft itself.

Cultural context preservation matters profoundly. The handmade leather jutti process carries stories, values, and identities within its techniques. Supporting authentic production maintains these cultural connections rather than reducing them to decorative aesthetics. Wearers become bridges between traditional knowledge and contemporary life, carrying forward meanings that would otherwise disappear.

Environmental sustainability emerges naturally from authentic practices. Vegetable tanning, natural dyes, material conservation, and product longevity in the handmade leather jutti process represent pre-industrial sustainability now desperately needed in our consumption patterns. Choosing quality over quantity, repair over replacement, aligns with ecological responsibility in ways fast fashion never can.

Educational value extends beyond the immediate purchase. Each authentic piece becomes a conversation starter about craftsmanship, heritage, and conscious consumption. This awareness spreading represents perhaps the most powerful preservation tool—creating markets that value authenticity and teaching new generations why handmade matters in a machine-made world.

The Future Trajectory: Innovation Within Tradition

The handmade leather jutti process evolves while maintaining core principles. Contemporary collaborations between designers and artisans create exciting innovations: minimalist designs highlighting craftsmanship, fusion styles blending traditional techniques with modern aesthetics, sustainable material experiments, and technological integrations that enhance rather than replace handwork.

Digital platforms revolutionize access without compromising quality. Artisans now reach global markets directly through social media and specialized marketplaces. Customers enjoy virtual consultations for custom designs. This digital bridge creates economic opportunities while maintaining artistic control where it belongs—with the makers themselves.

Educational initiatives ensure knowledge transmission. Documentaries, workshops, apprenticeship programs, and digital archives capture techniques before masters disappear. Museums increasingly recognize traditional shoes as cultural artifacts worthy of preservation and study. This institutional recognition validates what communities have known for centuries—this craftsmanship represents significant cultural achievement.

Material innovation expands possibilities within the handmade leather jutti process. Vegan alternatives using plant-based materials appeal to changing values while maintaining handmade integrity. Upcycled materials transform waste into beauty. Experimental natural dyes create previously impossible colors. These innovations demonstrate the craft’s adaptability—its ability to absorb new ideas while maintaining essential character.

The luxury repositioning of authentic ethnic footwear represents perhaps the most significant shift. As consumers tire of impersonal mass production, they increasingly seek products with stories, soul, and sustainability. Handmade juttis perfectly fulfill this desire—offering uniqueness, heritage, quality, and ethical production. This repositioning creates economic models where artisans receive proper compensation for their extraordinary skills.

Youth engagement determines ultimate survival. Surprisingly, many young artisans now choose this path, bringing fresh perspectives while respecting traditions. They document processes on social media, create contemporary designs, and find pride in continuing family legacies. This generational renewal suggests the handmade leather jutti process will continue evolving while maintaining its essential soul.

Conclusion: Walking with Intention, Standing with Heritage

The handmade leather jutti process represents humanity at its most creative—transforming humble materials into objects of beauty, function, and meaning through skill, patience, and tradition. Each stage from leather selection to final polishing carries intelligence accumulated over generations. This knowledge, embedded in hands more than books, represents cultural wealth beyond monetary value.

Your understanding of this process now equips you to make transformative choices. You can distinguish authentic ethnic footwear from clever imitations. You can support artisans directly, ensuring fair compensation for extraordinary skill. You can own traditional shoes that improve with age, telling your story alongside centuries of heritage. You become part of preservation simply through conscious consumption.

The six secrets revealed here—material reverence, pattern intelligence, cutting precision, embroidery artistry, structural integrity, and finishing perfection—provide your roadmap to authenticity. Apply them not just to juttis but to all handmade goods. Let them guide you toward products with soul in a world increasingly filled with soulless simulations.

Remember that every authentic pair connects you to human hands, cultural memory, and sustainable values. They represent resistance to disposability, celebration of diversity, and investment in beauty that lasts. When you next shop for traditional shoes, look beyond surface appearance to underlying process. Choose pieces that honor the handmade leather jutti process in all its remarkable complexity.

Your feet will enjoy unparalleled comfort. Your conscience will appreciate ethical production. Your spirit will connect to living heritage. And somewhere, an artisan will continue traditions because you recognized their value. This circular relationship—appreciation supporting preservation—represents our hope for keeping handmade excellence alive in an automated world.

Step forward in authenticity. Carry heritage gracefully. And remember: the most beautiful journeys begin with steps taken in shoes made with intention, skill, and soul.