Table of Contents

9 Essential Techniques Behind Traditional Handmade Juttis: A Journey in Craftsmanship

Introduction: Stepping into a Legacy

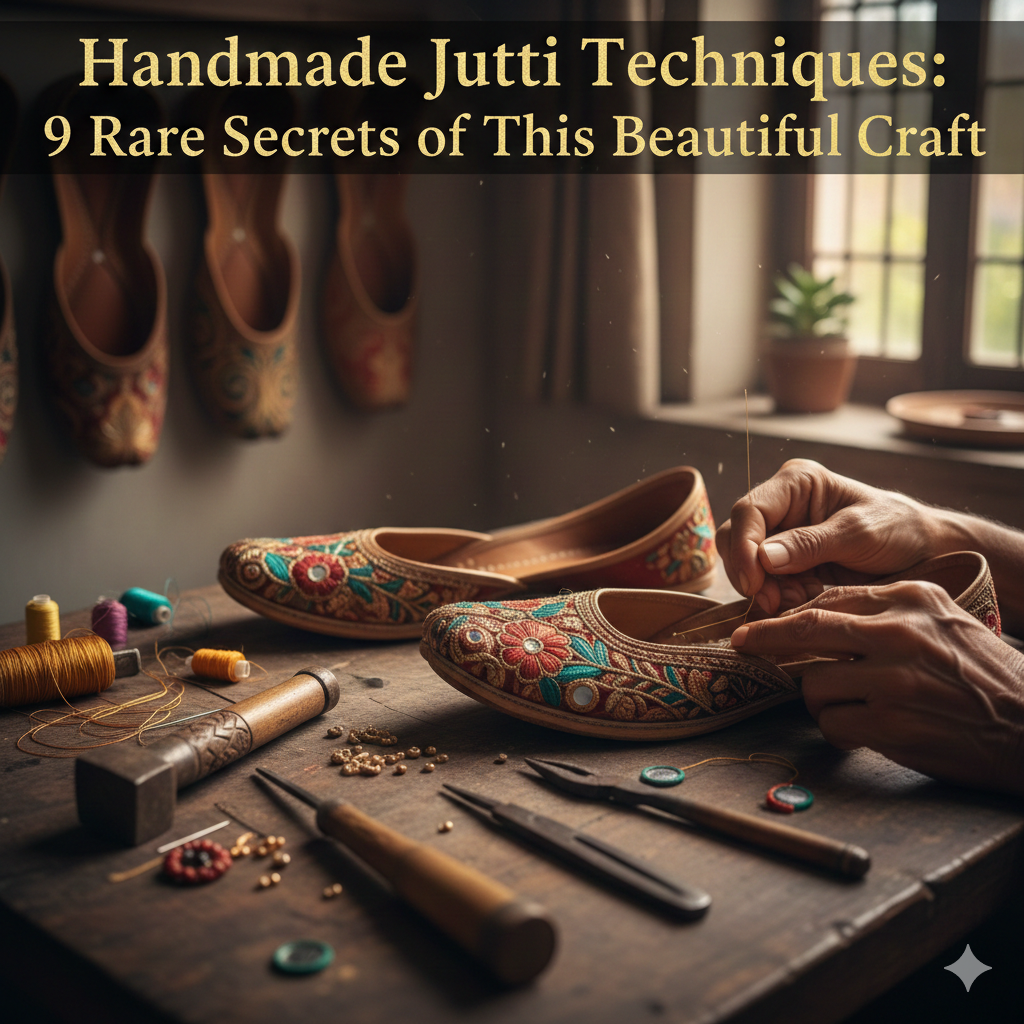

Welcome to the colorful, intricate world of handmade juttis. These traditional footwear pieces are more than just shoes. They are cultural narratives stitched onto leather. They represent centuries of artisan skill passed down through generations. In an age of mass production, handmade jutti techniques keep a tangible heritage alive. Each pair tells a unique story of craftsmanship.

This blog will walk you through the nine essential techniques that define this art. We will explore the meticulous processes behind handcrafted leather footwear. You will discover why these shoes are cherished globally. From selecting the right hide to the final decorative stitch, every step is deliberate. It is a slow, respectful dance between artisan and material.

Join us as we unravel the secrets behind these beautiful creations. Learn what makes traditional juttis a symbol of elegance and durability. Understand the skills required to produce each pair. Appreciate the human touch in a world increasingly dominated by machines. Let’s begin this journey into the heart of traditional footwear artistry.

1. The Art of Material Selection: Choosing the Perfect Hide

The foundation of any great handcrafted leather product is its material. For juttis, this process is both a science and an intuition. Artisans begin by selecting the perfect animal hide. Goat and camel leather are perennial favorites. They are prized for their softness, flexibility, and grain.

The selection process is rigorous. Artisans examine the hide for uniform thickness. They look for a smooth, blemish-free surface. The hide must be strong yet supple. It should mold to the foot’s shape without losing its structure. This choice directly impacts comfort, durability, and the final aesthetic. A superior hide accepts dyes and embroidery beautifully.

This step ensures the traditional footwear is built to last. It highlights the artisan’s deep understanding of their primary medium. It is the first critical technique in a long chain of craftsmanship. Without the right leather, even the most skilled hands cannot create a perfect jutti.

2. Pattern Making & Cutting: The Architectural Blueprint

Once the leather is chosen, the vision takes shape. Pattern making is the architectural stage of handmade jutti techniques. It involves creating precise paper templates for every shoe component. This includes the upper sole, the vamp (front piece), and the side panels.

Artisans use age-old patterns, often handed down through families. Yet, they skillfully adapt them for modern foot sizes and styles. The template is placed on the leather. Then, using sharp, specialized knives, the artisan cuts each piece. This requires a steady hand and an expert eye.

Accuracy here is non-negotiable. A mis-cut can waste precious material and compromise the shoe’s fit. This technique translates a two-dimensional design into three-dimensional reality. It is where the handcrafted leather first begins to resemble footwear. The precision of this step sets the stage for all subsequent artistry.

3. Molding & Lasting: Shaping the Foundation

This is where the flat pieces of leather begin to form a shoe. “Lasting” refers to stretching and securing the leather upper over a foot-shaped mold called a “last.” This technique is crucial for achieving the iconic, comfortable fit of traditional footwear.

The dampened leather is carefully pulled over the wooden last. The artisan uses pliers and tacks to stretch it taut. This process defines the shoe’s volume, toe shape, and overall silhouette. For juttis, this often means creating a snug yet forgiving fit around the foot’s contours.

It’s a physically demanding technique requiring significant strength and finesse. The goal is to eliminate wrinkles and ensure smooth, even tension. This step permanently sets the shoe’s structure. It is a core handmade jutti technique that machines struggle to replicate perfectly. The human touch ensures each pair accommodates the natural movement of the foot.

4. Hand-Stitched Construction: The Backbone of Durability

While some modern methods use glue, traditional juttis are built to last with needle and thread. Hand-stitching is the backbone of authentic handcrafted leather juttis. It involves sewing the upper pieces to the sole using a strong, waxed thread.

Artisans use two needles, working from both sides of the leather. This creates a sturdy, locked stitch that is incredibly resilient. The famous “Mochi” stitch, a hallmark of quality, is a result of this method. It allows the shoe to flex with the foot without the threads snapping.

This technique is time-consuming but irreplaceable. It provides superior durability compared to machine stitching. The stitches also add a subtle decorative element to the shoe’s profile. This commitment to hand-stitching is what makes traditional footwear like juttis heirloom pieces. They can be repaired and cherished for decades.

5. Embroidery & Embellishment: The Canvas Comes Alive

Perhaps the most visually stunning of all handmade jutti techniques is embroidery. This is where the leather transforms into a canvas for storytelling. Artisans employ a variety of stitches—zardozi (metallic thread), mokaish (flat wire), aari (chain stitch), and phulkari (floral patterns).

Using a small, hooked awl (the aari), they create intricate patterns inspired by nature, architecture, and folklore. Mirrors (shisha), beads, sequins, and stones are often incorporated. This stage requires immense concentration, creativity, and a flawless sense of design symmetry.

Each region has its signature style. Punjabi juttis are known for their vibrant colors and bold patterns. Rajasthani juttis often feature delicate, detailed threadwork. This embellishment technique elevates the handcrafted leather from simple footwear to wearable art. It is a slow, meditative process that imbues each pair with a unique soul.

6. Sole Attaching & Finishing: Building Resilience from the Ground Up

A beautiful upper needs a strong foundation. Attaching the sole is a critical handmade jutti technique that determines longevity. Traditional juttis often use multiple layers of leather for the sole. These are glued and then stitched together for added strength.

The finished upper is aligned perfectly with the sole stack. Artisans then use long, sturdy stitches to marry the two components. This perimeter stitching is a final testament to the shoe’s handcrafted quality. After stitching, the sole edges are filed smooth and often painted or finished with a protective coat.

This technique ensures the shoe can withstand daily wear. It provides the necessary grip and cushioning. The focus on a robust, multi-layered sole is a hallmark of thoughtful traditional footwear design. It proves that these shoes are made for both celebration and everyday life.

7. Coloring & Dyeing: A Spectrum of Tradition

Color breathes life into the handcrafted leather. Traditional dyeing techniques use natural and chemical dyes to achieve a vast spectrum. Artisans often hand-paint or dip-dye the leather pieces before assembly. This allows for stunning gradients and precise color blocking.

A key technique is “antiquing” or “patina creation.” Darker dyes are applied to crevices and edges. This highlights the shoe’s texture and embroidery, giving it a rich, dimensional look. The process requires an understanding of how colors interact with leather. It also needs skill to ensure even coverage without stiffening the material.

The choice of color is deeply cultural. Reds and pinks signify celebration. Gold and silver denote luxury. Earthy tones reflect a connection to nature. This handmade jutti technique is where personality is infused. It turns a constructed object into an expressive accessory.

8. Inlay & Appliqué Work: Adding Dimension

Beyond embroidery, artisans use inlay and appliqué to create texture. Inlay involves cutting a shape from the base leather and filling it with a contrasting piece. This creates a smooth, integrated design. Appliqué involves stitching a pre-cut leather shape onto the base.

These handmade jutti techniques add incredible depth and visual interest. Floral motifs, geometric patterns, and even figurative designs come alive in 3D. Working with multiple leather layers this way demands exceptional precision with cutting and stitching.

This technique showcases the artisan’s mastery over their medium. It demonstrates an advanced understanding of positive and negative space. The result is a piece of traditional footwear that is tactile and visually complex. It invites touch and closer inspection, revealing new details with every look.

9. Final Polishing & Quality Assurance: The Last Touch

The final technique is all about perfection. Once assembled, the jutti undergoes rigorous finishing. Artisans buff the leather to a soft sheen using natural waxes or creams. This protects the material and enhances its color. Any loose threads are trimmed. Embellishments are checked for security.

Every stitch, seam, and edge is inspected. The pair is compared for symmetry in design, color, and shape. This quality assurance step is what separates mass-produced items from true handcrafted leather masterpieces. It is the artisan’s pride in their work manifesting as a final, meticulous review.

This last touch ensures the traditional footwear is not just beautiful but also impeccable in construction. It is the promise of comfort and quality that the wearer will experience with every step. It closes the cycle of creation, readying the jutti for its journey to a new owner.

Conclusion: More Than Shoes, A Cultural Heritage

The nine handmade jutti techniques we’ve explored form a symphony of skilled labor. From hide to finished product, each step is a testament to human dedication. These methods preserve the integrity of handcrafted leather work. They ensure that traditional footwear remains relevant in our modern wardrobes.

Choosing handmade juttis means supporting sustainable practices. It values quality over quantity. It keeps ancient crafts and artisan communities thriving. Each pair you own carries the energy of the hands that made it. They are shoes with a story, a soul, and a purpose beyond mere fashion.

We hope this deep dive inspires you to appreciate the artistry behind your accessories. The next time you see a pair of juttis, look closer. See the precise cut, the tiny stitches, the vibrant embroidery. Remember the nine techniques. And step forward in the knowledge that you are wearing a piece of living heritage.

Image Credits & Suggestions for Implementation:

Note for the Blogger: To implement this blog post, please source high-quality, royalty-free images that match the descriptions provided. Ideal platforms include Unsplash, Shutterstock, or Adobe Stock. Use the suggested alt-text (in the image captions above) for SEO. Ensure images are optimized for web (compressed, correct dimensions) to maintain site speed. Space the images evenly throughout the post to break up text and enhance reader engagement.