Table of Contents

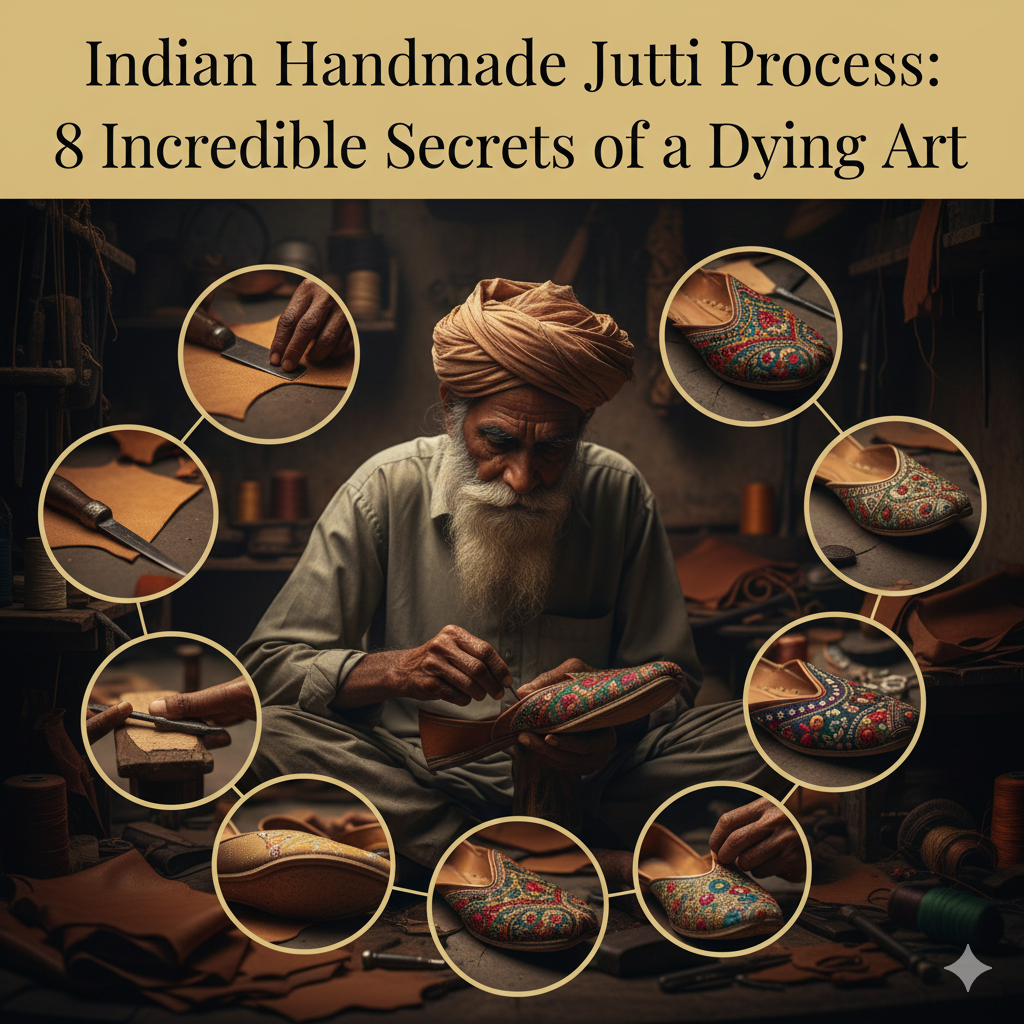

Title: Indian Handmade Jutti Process: 8 Incredible Secrets of a Dying Art

Meta Description: Discover the fascinating Indian handmade jutti process. Uncover 8 incredible secrets behind crafting these handcrafted shoes and why this art of ethnic footwear deserves preservation.

(Image 1: A wide-angle shot inside a traditional jutti workshop in Punjab or Rajasthan. Sunlight streams in, illuminating multiple artisans at different stages of work—cutting, embroidering, lasting. Alt Text: Inside a traditional workshop where the authentic Indian handmade jutti process brings handcrafted shoes to life.)

Introduction: The Whisper of a Thousand Stitches

In the quiet corners of India’s bustling cities and serene villages, a symphony of skilled hands works against time. This is the world of the Indian handmade jutti process. More than just shoemaking, it is a cultural legacy stitched into existence, one deliberate motion at a time. These handcrafted shoes represent a lineage of artistry that mass production cannot replicate.

Yet, this profound craft faces the threat of fading into obscurity. As a beacon of authentic ethnic footwear, the jutti’s creation is filled with hidden intricacies known only to its keepers. This exploration uncovers eight incredible secrets behind this dying art. We reveal why each step, from selecting leather to the final polish, is an act of preservation. Join us in understanding a craft where every pair tells the story of a disappearing world.

Secret #1: The Soul Lies in the Leather – A Sacred Selection

The journey of ethnic footwear begins not with a stitch, but with a sacred choice. The soul of the Indian handmade jutti process is the leather. Artisans do not use just any hide; they seek perfection. Goat leather, known as chamri, is preferred for the upper. Its fine grain and soft pliability make it ideal for intricate embroidery without tearing. For the robust sole, water buffalo or cow leather is chosen for its density and longevity.

The secret lies in the pre-work. The leather is vegetable-tanned using natural barks and leaves, not harsh chemicals. This age-old method makes it breathable, supple, and develops a rich patina over time. Selecting the right piece for the right part—avoiding scars or uneven textures—is an intuitive skill. This foundational step ensures the handcrafted shoes are durable and comfortable from their very core.

Secret #2: The Dance of the Ari and Sui – Tools as Extensions of Self

In a modern factory, machines whir with impersonal efficiency. In a jutti workshop, the primary tools are humble extensions of the artisan’s own body. The Ari, a uniquely curved awl, and the Sui, a stout needle, are the unsung heroes of the Indian handmade jutti process.

The Ari’s curvature is not an accident. It is engineered to pierce through multiple layers of leather at the precise angle needed for the mochi (cobbler) stitch. The artisan’s wrist executes a fluid, rolling motion to drive it in and out cleanly. The Sui then follows this pre-made path, pulling through the thick, waxed thread. This manual piercing prevents the leather from tearing, a common flaw in machine-punched holes. Mastery over these simple tools is the first great secret, transforming basic materials into the foundation of legendary handcrafted shoes.

(Image 2: An extreme close-up on an artisan’s hands using the curved ari awl to pierce a leather sole, with a spool of thick waxed thread in the foreground. Alt Text: The curved ari awl is a specialized tool central to the traditional Indian handmade jutti process for ethnic footwear.)

Secret #3: Embroidery – Where Geometry Meets Freehand Poetry

The dazzling embroidery on ethnic footwear is often mistaken for repetitive patterning. The secret is that it is a breathtaking fusion of strict geometry and freehand expression. Before any thread touches leather, the design is mapped. Sometimes, a basic outline is traced using a pencil or shel. For incredibly complex patterns, artisans use a pouncing technique.

They prick holes along a paper stencil and dab powdered chalk through it, transferring the guide. Then, the embroidery begins. Using an ari for Aari work or a simple needle for soof or pakko stitches, the artisan fills the design. The true secret is the lack of mechanical guides. The spacing, tension, and curvature of each stitch are judged by the eye and muscle memory. A single motif, like a phool (flower) or mor (peacock), might consist of hundreds of micro-stitches, each placed with poetic precision. This transforms the handcrafted shoes into a canvas of wearable art.

Secret #4: The Invisible Mochi Stitch – Structural Sorcery

While embroidery garners awe, the true strength of ethnic footwear is hidden in a magical stitch few ever see. The Mochi stitch (or tanki) is the structural sorcery of the Indian handmade jutti process. After the embroidered upper is perfectly stretched over a wooden last (foot-shaped mold), the artisan works from the inside. Using the ari, they pierce from the inside of the upper through to the insole.

They then use the sui to pull the waxed thread through in a powerful backstitch. The genius? This stitch is completely invisible on the outside sole. It creates a flexible, muscular bond between the upper and the sole that moves with the foot. This technique prevents the sole from detaching—a frequent failure in glued, machine-made shoes. This hidden, internal lock is a master secret, guaranteeing the longevity that defines genuine handcrafted shoes.

Secret #5: The Wooden Last – The Silent Architect

The form of every jutti is sculpted not by a machine, but by a silent wooden architect: the Last. This is not a generic shoe mold. In traditional practice, a last was often custom-carved for a specific client, capturing the unique contours of their feet. In the Indian handmade jutti process, the last is the transformative bridge between a flat piece of art and a three-dimensional shoe.

The secret technique is in the “lasting.” The embroidered leather upper is slightly dampened to increase pliability. It is then painstakingly stretched, pulled, and tacked over the last. The artisan must apply perfect, even tension in all directions. This ensures the design sits correctly on the curved surface and the shoe achieves its graceful, ergonomic shape. The ethnic footwear’s comfort and elegant silhouette are born in this intimate, physical dialogue between soft leather and hard wood.

(Image 3: A wooden last with a half-formed jutti stretched tightly over it, showing tacks holding the leather in place. Other lasts sit in the background. Alt Text: The wooden last is crucial in the Indian handmade jutti process, shaping handcrafted shoes into perfect form.)

Secret #6: The Layered Sole – A Saga of Resilience

A jutti’s sole is not a slab; it is a saga of layered resilience. This is a cornerstone secret of durable handcrafted shoes. The sole is built from three to five layers of thick buffalo leather. Each layer has a purpose. The innermost layer is the platform. Subsequent layers are progressively smaller, building a rounded, protective edge that cushions the foot. These layers are first bonded with a natural adhesive, often a glue made from animal collagen.

Then, they are stitched together using the strong bakhiya or panja stitch, sometimes with a double needle creating parallel lines. This composite construction is revolutionary. It absorbs shock, insulates from ground temperature, and allows for repair. When the bottom layer wears thin, a cobbler can simply stitch on a new one, giving the ethnic footwear multiple lifetimes. This built-in sustainability is a forgotten wisdom of the Indian handmade jutti process.

Secret #7: Gota & Kinari – The Precision of Fire

The application of Gota (metallic ribbon) and Kinari (edging lace) is where precision meets pressure. This stage, often handled by women artisans, is deceptively delicate. The secret technique is in the attachment. The thin, fragile gota is not sewn through its center, which would cause it to curl and break. Instead, the artisan uses a nearly invisible straight stitch or a catch stitch along its very outer edge.

For intricate shapes—like forming a perfect petal or leaf—the gota is folded and pinched into shape with fingertips before being secured. This requires supernatural steadiness and spatial intelligence. A single millimeter of slippage can ruin the symmetry of an entire pattern. This high-stakes, luminous work adds the regal shimmer to the handcrafted shoes, representing a pinnacle of patience in the Indian handmade jutti process.

(Image 4: A close-up of a woman’s hands meticulously folding and stitching narrow gota ribbon onto a jutti upper, creating a precise floral pattern. Alt Text: Applying gota ribbon is a precise and delicate stage in creating handcrafted ethnic footwear.)

Secret #8: The Final Breath – Polishing & Imbuing Spirit

The final secret is not a technical step, but a ceremonial one: imparting the finishing breath. After the sole is attached and the last removed, the ethnic footwear seems complete. But for the artisan, it is not yet alive. The process of sajaavat (finishing) begins. Any rough edges on the sole are sanded smooth. The entire shoe is polished with a natural wax or rogan (a traditional oil-based polish) using a soft cloth.

This nourishes the leather, enhances its color, and provides a protective layer. More than function, this is an act of imbuing spirit. The artisan examines every angle, feels every seam, and ensures symmetry. It is a moment of quiet pride and release. This final, attentive breath transforms the assembled object into a pair of handcrafted shoes ready to walk into someone’s life, carrying the energy of the hands that made them.

Why This Art is Dying & The Glimmer of Hope

Knowing these eight secrets makes the craft’s precarious state more poignant. The Indian handmade jutti process is dying due to a brutal convergence of forces. Cheap, machine-made replicas flood the market, undercutting authentic artisans who cannot compete on price alone. The younger generation, witnessing the economic strain and physical toll, often seeks less demanding work.

The intricate knowledge, passed orally and through demonstration, risks disappearing with each elder artisan. However, a glimmer of hope persists. Conscious consumers globally are seeking sustainable, ethical ethnic footwear. Designers are collaborating with artisans for contemporary collections. NGOs and cooperatives are helping with direct market access and fair wages. By choosing genuine handcrafted shoes, you become part of this hope. You vote for a world where such beauty and skill are valued and preserved.

How You Can Identify & Support True Handmade Juttis

To support this art, you must first be able to identify it. Look for the hallmarks of the true Indian handmade jutti process. Check the stitches: Hand-stitching, especially on the sole, will have slight, natural inconsistencies. Machine stitching is perfectly uniform. Feel the inside: The interior will have a rough, unfinished leather texture, not a synthetic lining. Examine the embroidery: Flip the shoe over.

On the inside, you will see the backs of stitches—small knots and thread tails. Machine embroidery has a uniform, fabric-like backing. Smell it: Genuine vegetable-tanned leather has a rich, earthy smell. Synthetic materials smell chemical. Ask questions: Support brands and sellers who transparently discuss their artisans and processes. Your informed purchase is the most powerful tool for ensuring the eight incredible secrets of this ethnic footwear continue to be told, one exquisite pair at a time.

(Image 5: A split-image showing a genuine handmade jutti (left) and a machine-made copy (right). Arrows point to key differences: hand-stitching vs. uniform stitching, natural grain vs. perfect pattern, rough interior vs. smooth lining. Alt Text: Learning to identify true handcrafted shoes is key to supporting the authentic Indian handmade jutti process.)

Conclusion: Carrying a Legacy Forward, One Step at a Time

The Indian handmade jutti process is a testament to human ingenuity, patience, and cultural pride. These eight incredible secrets—from the sacred leather and the dance of the ari to the invisible stitch and the layered sole—reveal a universe of wisdom in a single pair of shoes. This craft is more than a method; it is a philosophy where quality triumphs over speed, and connection outweighs convenience.

As a beloved form of ethnic footwear, each jutti is a vessel of history. In choosing these handcrafted shoes, you do more than accessorize. You become a custodian of a dying art. You provide the oxygen that allows this ancient flame to keep burning. You carry a legacy forward, ensuring that the whisper of a thousand stitches is not silenced, but continues to echo with every beautiful, intentional step taken into the future.